Be part of

the cycle

Join leading door and window manufacturers on the cutting edge of performance and the circular economy. Add the SILENSIA patio door featuring NUCLEUS technology to your product offer today.

SILENSIA PATIO DOORS

The first patio doors with NUCLEUS technology. They are the first in North America to feature profiles containing high-performance cores made almost exclusively of recycled PVC.

AVAILABLE NOW

INTRODUCING NUCLEUS TECHNOLOGY

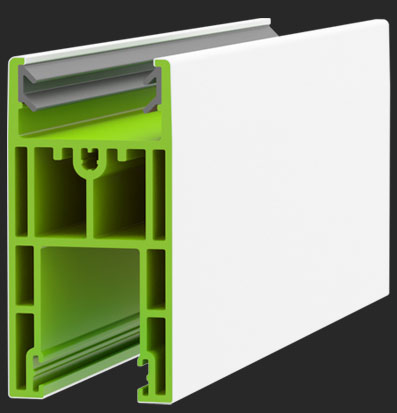

Profile core made almost exclusively of recycled PVC

NUCLEUS technology is a P.H. Tech innovation that allows window and door manufacturers to offer environmentally friendly products without compromising on performance or price. Only the outer shell contains virgin PVC, ensuring a flawless, uniform appearance.

THE NUCLEUS SEAL

SETS YOUR PRODUCTS APART

NUCLEUS is ideal for architects, contractors, and homeowners who wish to use environmentally friendly products. The NUCLEUS seal represents efforts to reduce environmental impacts and ensure recycled PVC delivers the same performance as virgin material.

TECHNOLOGY

Eco-efficient profile

- Contains up to 100% recycled PVC

- Retains 100% of structural and thermal properties

- Performance exceeds AAMA quality standards

CORE

The multiple inner chambers that form the profile’s core contain up to 100% recycled PVC. Our recycled PVC is light gray in color to ensure strict quality control and maintain transparency with our clients. The color is not visible on the finished product.

WELDED PROFILE

The profile’s outer walls are made of virgin PVC. They guarantee a flawless appearance. The core and walls are coextruded, and the contact points that bind them together are fused using the same process as a virgin profile.

MECHANICALLY

ASSEMBLED PROFILE

All parts of the core that could potentially be exposed to sunlight are covered by a virgin PVC shell, ten times thicker than PVC paint. The core and shell are coextruded. The recycled PVC is not visible once the product is assembled.

BENEFITS

Why use virgin PVC when our 100% recycled PVC performs just as well?

Consumers are demanding environmental responsibility, and rightly so. We share their concerns, and we too believe that change starts at home. Let’s be the change we seek.

FOR CONSUMERS, THE DECISION TO BUY IS SIMPLE

ECO-EFFICIENT

THE GREENEST CHOICE

NO COMPROMISES

BETTER LOOKS, DURABILITY, AND PRICE

SOLID WARRANTY

THE SAME AS FOR OUR TOP-QUALITY VIRGIN PVC PRODUCTS

Green solution.

Uncompromising performance.

SMALLER ENVIRONMENTAL FOOTPRINT

We have set up our network of qualified suppliers to reduce carbon emissions by limiting the need for transport. This helps us reduce the environmental footprint of the entire supply chain.

P.H. TECH QUALITY

We require our post-production PVC suppliers to meet demanding specifications and undergo a strict quality control process to ensure our PVC is top quality and AAMA certified.

STRONG AND DURABLE

Thanks to our sophisticated and intelligent cutting-edge equipment, the structural and thermal performance of our recycled PVC profiles is on par with that of our virgin PVC profiles.

UNIVERSAL SOLUTION

Our innovative technology means recycled PVC cores can be integrated into all types of PVC doors and windows, along with welded and mechanically assembled profiles.

Taking care of the planet

shouldn’t cost extra

We redesigned our profiles, improved our manufacturing processes, and set up a reliable supply system for recycled PVC. Every step along the way, we were mindful that our clients and their customers shouldn’t have to pay extra to protect the environment.

P.H. Tech products with NUCLEUS technology add a new dimension to your offer and help you stand out from the competition. You can offer a green option at no extra cost.

FAQ

DO YOU OFFER ANY OTHER PRODUCTS WITH RECYCLED PVC BESIDES THE SILENSIA PATIO DOOR?

Yes. We already offer a whole series of accessories that are very popular with manufacturers. We are also developing profiles for our windows. We put hundreds of R&D hours into each eco-friendly profile to make sure it meets the high quality standards our clients have come to expect.

IS RECYCLED PVC AS DURABLE AS VIRGIN PVC?

Yes. PVC is recyclable by design. Independent tests have shown that PVC can be recycled several times without compromising performance if the melting process is carried out properly. Given that PVC retains its properties and a good PVC window has a minimum lifespan of 20 years, the same material can be reused for over a century.

WHY COVER THE RECYCLED PVC CORE WITH A VIRGIN PVC SHELL?

For aesthetic reasons only. We understand how important looks are when it comes to doors and windows. The virgin PVC shell or wall means homeowners can count on a UV-resistant flawless product.

WHY ISN’T RECYCLED PVC WHITE?

We have chosen to make our recycled PVC light gray for operational and quality control reasons. The color makes it easier to standardize production. Plus, manufacturers are able to tell the difference between eco-friendly and standard profiles at a glance. The color also reflects our desire to be transparent with our clients, to whom we are committed to delivering eco-friendly profiles.

IS THE RECYCLED PVC POST-PRODUCTION OR POST-CONSUMER?

We currently use only post-production PVC. Due to the way recyclables are collected in North America, we are unable to obtain post-consumer PVC at the moment. It is possible in Europe as part of a sustainable development initiative, so it’s likely that we’ll eventually be able to source post-consumer PVC in North America. We have gone to great lengths to ensure our production processes are on the cutting edge. As a result, P.H. Tech is ready to use post-consumer PVC when it becomes available.

IS THE PRODUCT WARRANTY THE SAME?

Yes. When processed correctly, extruded recycled PVC retains its physical properties. P.H. Tech’s rigorous and consistent quality control allows us to offer the same warranty for both recycled and virgin PVC.

DOES ACQUIRING RECYCLED PVC REQUIRE ADDITIONAL TRANSPORT?

No, quite the opposite. Reducing our environmental footprint is one of our core objectives, so we weren’t satisfied with just recycling our own PVC. We developed a supply network with qualified nearby manufacturers that meet our quality criteria. This eco-friendly initiative has reduced the amount of transportation required and, as a result, our carbon emissions.

IS P.H. TECH’S COMMITMENT TO THE ENVIRONMENT NEW?

No. We have long been aware of our social and environmental responsibility. P.H. Tech has been working for decades to reduce waste, optimize energy and water consumption, and reduce the impact of transportation. NUCLEUS technology is part of these efforts and represents nearly a decade of hard work and investment. We are proud to have developed an eco-friendly technology that lives up to our quality standards.

DO PRODUCTS WITH NUCLEUS TECHNOLOGY COST MORE THAN STANDARD PRODUCTS?

No. Our next-generation profiles required major R&D investment. But taking care of the planet shouldn’t cost extra, and we have always kept that in mind when developing our technologies. We want our value-added products to be affordable. Being a responsible company means making eco-friendly products accessible. We are extremely proud to offer our recycled PVC profiles at the same price as our standard profiles.